La Vogue, when the city becomes a fun fair

Active Design

TF URBAN’s approach is innovative and differentiating, to think of tomorrow’s ways of living that are ever more sustainable, intelligent and user-friendly.

TF URBAN has been a partner of the International Design Biennial for 15 years, undertaking ambitious projects and choosing design as a lever for attractiveness. We stand alongside all those who want to change the lines to make our cities more beautiful and more pleasant to live in. Sharing the same mindset and speaking the same language as designers and architects, we propose new solutions that improve daily life to develop the attractiveness of neighborhoods.

Looking at the city with children’s eyes, we imagine playful furniture, capable of transforming the city into a place of celebration. On the occasion of the Banc d’essai event, supported by the Saint-Etienne International Design Biennial, we are presenting our latest innovation: La Vogue, design by Jean Couvreur.

Innovation

Design and feasibility

« Urban furniture responds to specific uses but can also appeal to our memories to transform, for example, a public square into a fairground.. »

Jean Couvreur

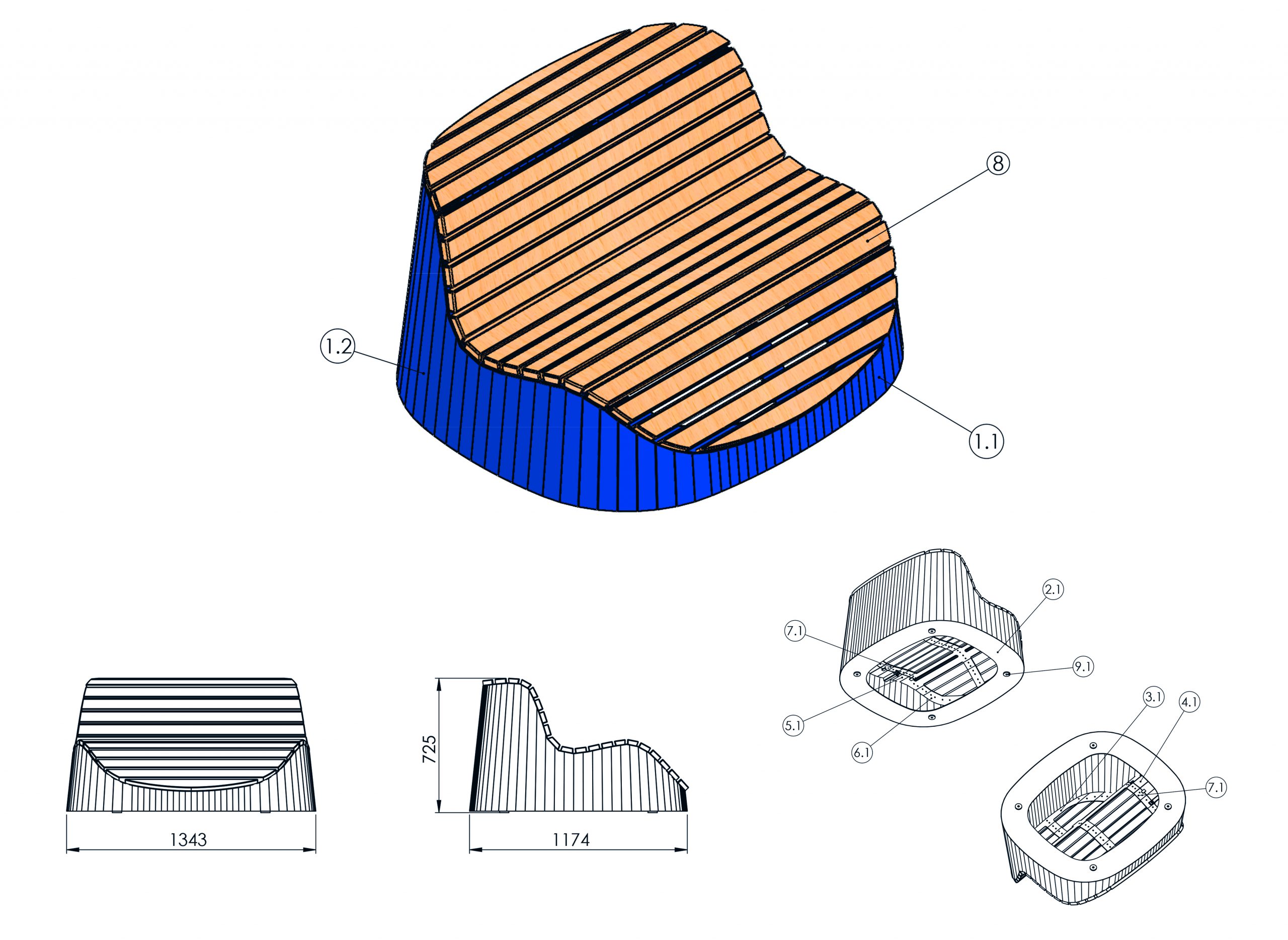

Jean Couvreur’s drawings are challenged by the TF Lab team, which interprets and translates the designer’s intentions. First confronted with industrial feasibility, the design is then transformed into sheet metal work. Everything is reviewed: the choice of materials, their shaping, the thicknesses, the choice of production tools, the optimization of materials, the size of the parts, the splitting and sizing of the parts according to the specifications (transport, installation, maintenance), the manufacturing steps and the realization of the manufacturing plans. All this is done in constant exchange with the designer. Once the plans are drawn up, this team ensures the follow-up of the manufacturing process and accompanies the key stages of manufacturing.

Under its pure and simple appearance, the implementation of these deckchairs is of high quality, in design and manufacturing. The central part of the deckchair is retractable thanks to a totally invisible mechanism. This option makes it easier to secure the furniture to the ground and to maintain it, and it also makes it easier for the installers to work.

“The project La Vogue, proposes to revitalize a place by installing urban furniture in the manner of a fairground (the term used La Vogue corresponds to the name of popular festival and fairground in the Rhone Alpes region).

The proposal takes the form of deckchairs designed in the manner of bumper cars (also called auto-butante in Mayenne where I come from*). These objects are arranged in the space in such a way as to reproduce the track of the merry-go-round while offering views on their environment.

They are seats for two people in a lounge position. The design is very simple creating graphic totems on the square. The structure is made of steel, the seat is made of wooden slats in order to offer a maximum of comfort to the user and to let the rainwater run off.”

Jean Couvreur

Folding metal

In the workshop, the steel sheets are first cut on a laser machine.

The folding of the steel sheets from 3 to 6mm is then done manually, on a folding machine, with the help of a plan and ribs, according to the technique of crocking. This is an essential step during which the volume is drawn in space. All the meticulousness and expertise of the folding worker is required to ensure a regularity of the fold and a perfect spatial projection.

Assembling

After the folding stage, the furniture is in volume, but still in the state of spare parts. The boilermaker first takes charge of the assembly of the metal parts. He carries out the operations of pointing to lock the form and control the geometry. He finalizes with a weld bead on the entire upper and lower periphery of the part. He is also responsible for the finishing operations, for a perfect harmonization of the assembled parts.

Painting and sublimation

To give the deckchair all its beauty, and to ensure its protection, the parts undergo a mechanical stripping, then are covered with a primary layer. After this treatment, they are painted with an epoxy powder which is baked at 200°.

This treatment protects the metal parts against corrosion. Thus, they resist the tests of the weather, wear and tear and time.